AI Models

Transforming the process of innovation

Exploring, deepening, and applying cutting-edge technologies in areas like automation, data science and the Internet of things, now INTERA is strongly betting in developing embedded AI solutions and accelerators focusing on optimizing computing performance, to make AI applications more efficient and more accesible to people.

AI Models

Our skilled AI model developers, specializing in the demanding areas Digital Health, energy management, industrial IoT, Automotive and image processing, provide comprehensive support in the creation, testing, and validation of AI models..

We prioritize accuracy and efficiency to meet performance standards and can seamlessly integrate these AI models into client´s software applications, delivering a complete solution for your customers.

Our AI model development services include:

AI Model Development

Our custom model design can significantly improve data analysis, predictive modeling, and decision-making processes.

Testing

This process includes performance testing, which evaluates speed and resource utilization, as well as accuracy testing to confirm the reliability of the results produced.

Integration

Our expertise allows us to develop standalone software solutions or integrate sophisticated algorithms and AI models into existing applications, ensuring seamless API development to enhance functionality and user experience.

Validation

Our validation process systematically ensures that the AI models accuracy and reliability in practical applications.

Documentation

By providing comprehensive documentation for algorithms and AI models, including user manuals, integration guides, and technical references, we ensure enhancing user experience and facilitating seamless integration.

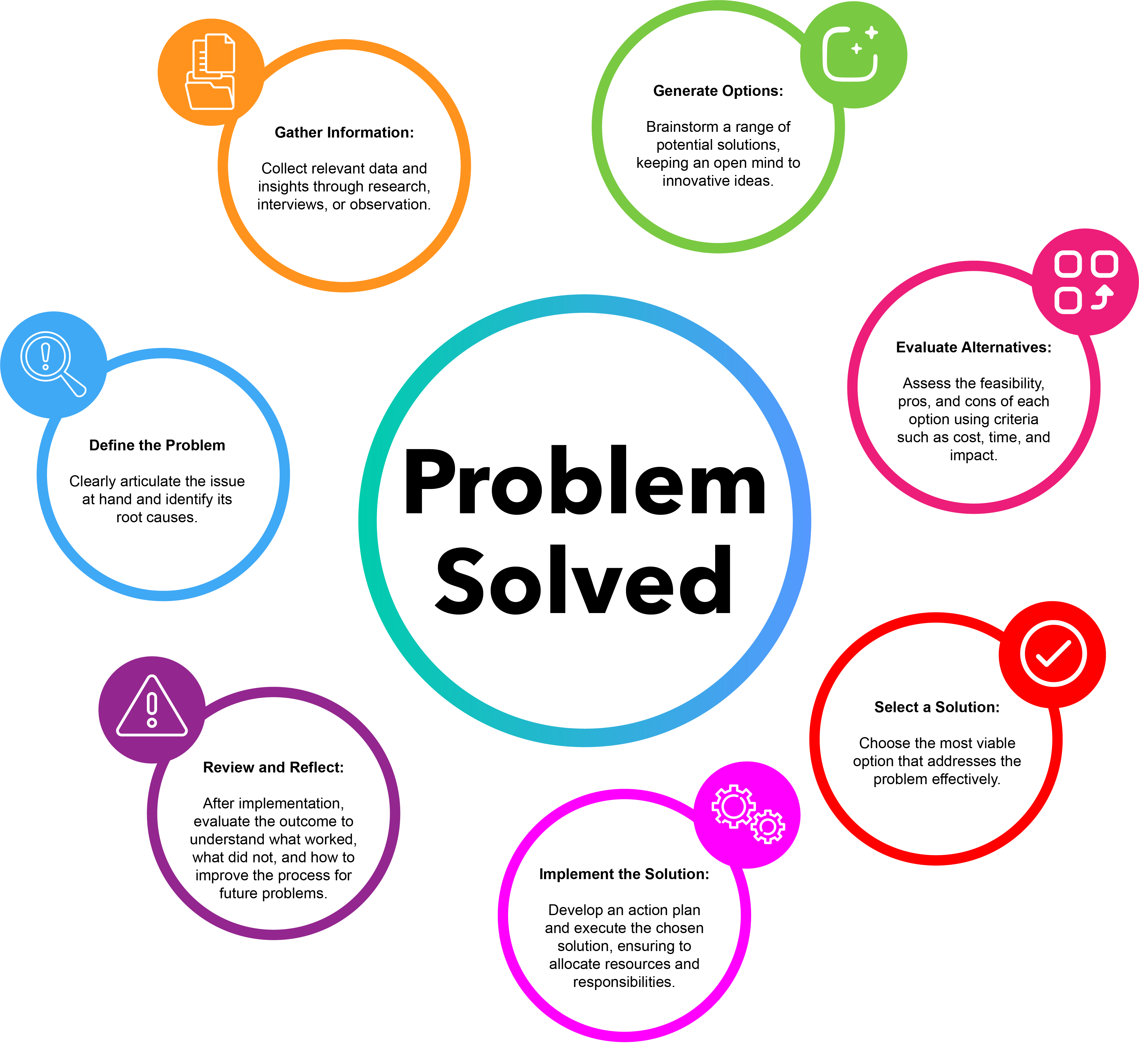

Problem Solved?

INTERA helps effectively solve complex problems, facilitating a structured approach that includes the following steps:

Technical data

Following some details of our technical data:

Time-Series Analysis Models.

For battery Management Systems (BMS), Industrial IoT and Digital for monitoring and predictions over time.

Physics-Informed AI Models:

For battery Management Systems (BMS), where integrating physical and chemical parameters improves the accuracy of State of Charge (SoC), State of Health (SoH), and Remaining Useful Life (RUL) predictions etc.

Convolutional Neural Networks

For automotive and Industrial imaging applications, such as driver monitoring, object detection, and defect detection in manufacturing processes.

Anomaly Detection Models:

For digital Health, BMS, and Industrial IoT to identify unusual patterns or outliers in data, which could indicate equipment failure, patient physiological anomalies, or operational inefficiencies.

Decision Trees and Random Forests:

Very useful and common in predictive maintenance for Industrial IoT, where interpretable models are preferred to facilitate straightforward insights into equipment failure probabilities and risk assessment.

Federated Learning Models:

Digital Health and distributed IoT environments or logistics, where data privacy is crucial, allowing models to be trained across multiple devices without sharing sensitive data.

Reinforcement Learning Models:

Useful in Industrial IoT and Automotive applications for optimizing dynamic processes, such as adaptive control systems and real-time decision-making.

Federated Learning Models:

Digital Health and distributed IoT environments or logistics, where data privacy is crucial, allowing models to be trained across multiple devices without sharing sensitive data.

Multi-Modal Sensor Fusion Models:

Digital Health or Automotive safety to integrate data from multiple sources (e.g., radar, temperature, motion sensors) for comprehensive monitoring of desirable parameters.

Support Vector Machines:

Very useful and common in predictive maintenance for Industrial IoT, where interpretable models are preferred to facilitate straightforward insights on equipment failure probabilities and risk assessment.

Graph Neural Networks:

Energy management and predictive maintenance in industrial IoT, where relationships and dependencies between components (e.g., sensors, equipment in a network) are crucial.

Support Vector Machines:

Very useful and common in predictive maintenance for Industrial IoT, where interpretable models are preferred to facilitate straightforward insights on equipment failure probabilities and risk assessment.

INTERA is made up of the most committed professionals in Europe who collaborate with clients to work towards creating the most advanced AI solutions & chip accelerators.

The company has developed innovative solutions for various applications, advancing the state of the art and creating value for its customers and partners.